Price of Your Temperature Data Logger is Always Lower than the Cost of Poor Quality (COPQ). (Case Study Included)

- Mettcover Global

- September 28, 2023

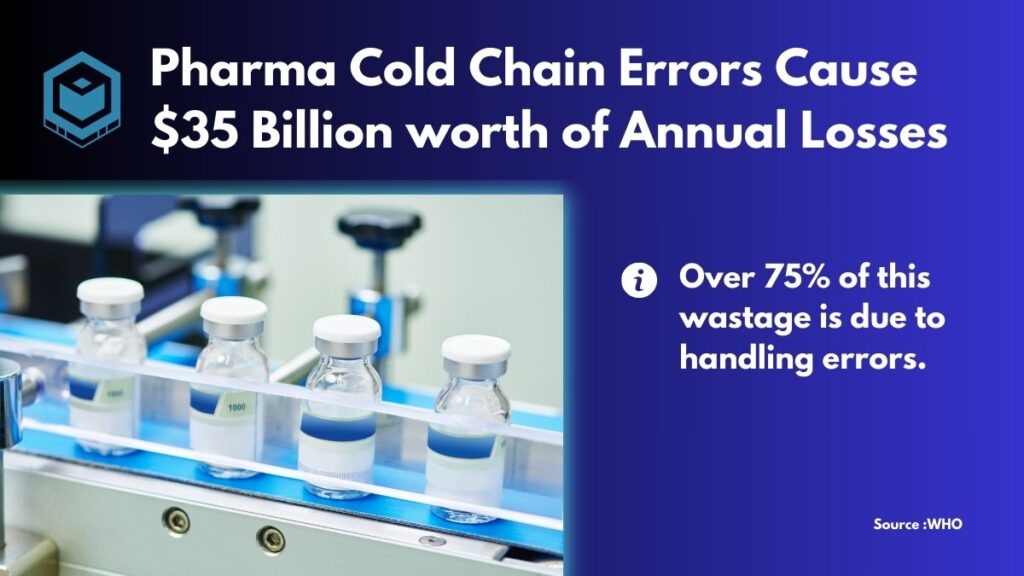

Let’s talk numbers. Have you ever paused to calculate the Cost of Poor Quality (COPQ) in your cold chain management. We mean the precise losses that you incur in the absence of precision data logging? Employing effective data loggers goes beyond their price tags. It is an investment strategy; if deployed with diligence and the right device, it will propel the tally of dollars saved. More so, in terms of your brand equity and reputational wealth.

The Profit equation: Cost of your temperature data logger is but a pixel in the big picture of your success.

Before we begin, let us simplify the background and create a level playing field for all readers; even the ones that are not too familiarized with the pharmaceutical cold chain management.

In the cold supply chain of medicines and vaccines , precision is not just a procedural compliance; it is a pressing necessity. The label, ”Handle with Care” takes an altogether new dimension. From the sterile environment of labs and manufacturing facilities to the shelves of the pharmacies, maintaining precise temperatures of medicines and vaccines is a non negotiable directive. Cold Chain planners invariably integrate “temperature data loggers” with their supply chain to monitor the shipments throughout their transit regime. The precision recording devices take a log of pallet temperature at every fixed interval (say every 5 minutes) and eventually deliver a comprehensive report of the temperature conditions of the entire journey.

It is duly noted that the cold supply chain of healthcare products is a complex process; it involves multi modal transits and at each step of the process, external heat threatens to penetrate the pallet load. If successful, any undesired heat excursion will render the products as compromised.

In other words, if the pharmaceutical products are not maintained at their optimum temperature, these shipments will be most likely rejected.

The health care shipments must maintain their potency and efficacy. For this, they need to be stored and transported within specific temperature ranges. This is where the cold chain comes into play—a temperature-controlled supply chain that ensures drugs remain within their required temperature thresholds from production to consumption.

For more information on how cold chain works, read our blog on popular Cold Chain FAQs

The temperature controlled logistic industry counts this imperative as a “Quality Management” paradigm and therefore, experts recommend “Economics of Quality” principles as a procedural guidance. This ideology narrates a strategic approach wherein the costs, investments, and returns associated with maintaining and elevating quality are meticulously analyzed. In the pharmaceutical industry, especially when dealing with temperature-sensitive products, maintaining an unbroken cold chain is mandatory.

Cold Chain Management & “Economics of Quality”

The genesis of the concept, “Economics of Quality” can be traced back to the mid-20th century. It is when the industrial revolution was at its peak, leading to the emergence of quality management pioneers. Figures like W. Edwards Deming, Joseph M. Juran, and Armand V. Feigenbaum laid the foundational principles. They emphasized the economic advantages tied to quality improvement within organizational processes. These stalwarts advocated for statistical methods, quality planning, and the concept of Total Quality Control and eventually gave birth to the concept, now known as “Economics of Quality” and today it extends well beyond manufacturing practices.

Cold chain specifiers and validators play a critical role in ensuring that the temperature-sensitive pharmaceuticals are transported and stored within the stipulated temperature range. The slightest deviation from this range could lead to compromised quality and efficacy, resulting in significant financial losses and potential risks to public health.

How Data Loggers impact Economics of Quality

The effectiveness and safety of drugs depends on the conditions they are exposed to, especially temperature and humidity. The cold chain data loggers continuously records temperature data, creating a chronological map of the pharmaceuticals’ journey. This data isn’t just a collection of numbers; it’s a narrative that reveals the environmental challenges the drugs face. Any deviation from the required temperature range is recorded and displayed in a detailed report. To Learn more about what exactly is a temperature data logger and how it works, read THIS BLOG.

While transporting temperature sensitive pharmaceutical shipments, inaccurate data logging, whether due to faulty equipment, incorrect placement of loggers, or a malfunction in the monitoring system, can have far-reaching consequences, directly impacting the COPQ (Cost of poor Quality) in the cold chain. Here’s how:

1. Loss of Product Efficacy:

Inaccurate data can lead to undetected temperature excursions, rendering the products ineffective or even harmful. This loss of efficacy translates to a direct financial loss and potential harm to consumers.

2. Compliance Issues:

Regulatory bodies impose strict guidelines on temperature control for pharmaceuticals and other temperature-sensitive products. Inaccurate data can lead to non-compliance, resulting in penalties, legal complications, and the need for expensive corrective actions.

3. Rejection of Shipments:

Many pharmaceuticals and perishable goods come with stringent temperature requirements. Inaccurate data can cause receivers to reject shipments due to uncertainty about the product’s quality. Rejections incur additional transportation and disposal costs.

4. Reputation Damage:

A significant consequence of inaccurate data is reputational damage. When a company’s products are compromised due to temperature issues, it erodes consumer trust and damages the brand’s reputation. Rebuilding this trust is a long and costly process.

5. Redundant Investigations:

Inaccurate data often necessitates extensive investigations to determine the cause of temperature excursions or product spoilage. These investigations consume valuable time and resources that could have been utilized more efficiently.

Cost of Poor Quality (COPQ) v/s the cost of a cheap data logger.

COPQ is a financial estimation that assesses various elements, including costs associated with prevention, appraisal, and failure. In the context of inaccurate data logging, COPQ involves costs such as:

Cost of Investigations:

The expenses incurred in investigating temperature excursions or discrepancies in data logging systems.

Cost of Disposal:

The cost of disposing of products that are compromised due to inaccurate temperature monitoring.

Cost of Replacements:

The expenses associated with replacing rejected or compromised products.

Legal and Compliance Costs:

Fines, penalties, legal fees, and other costs related to non-compliance with regulatory requirements.

Case Study – Averting a Crisis – Hepatitis Vaccines

Industry Challenge: Varying Environmental Conditions

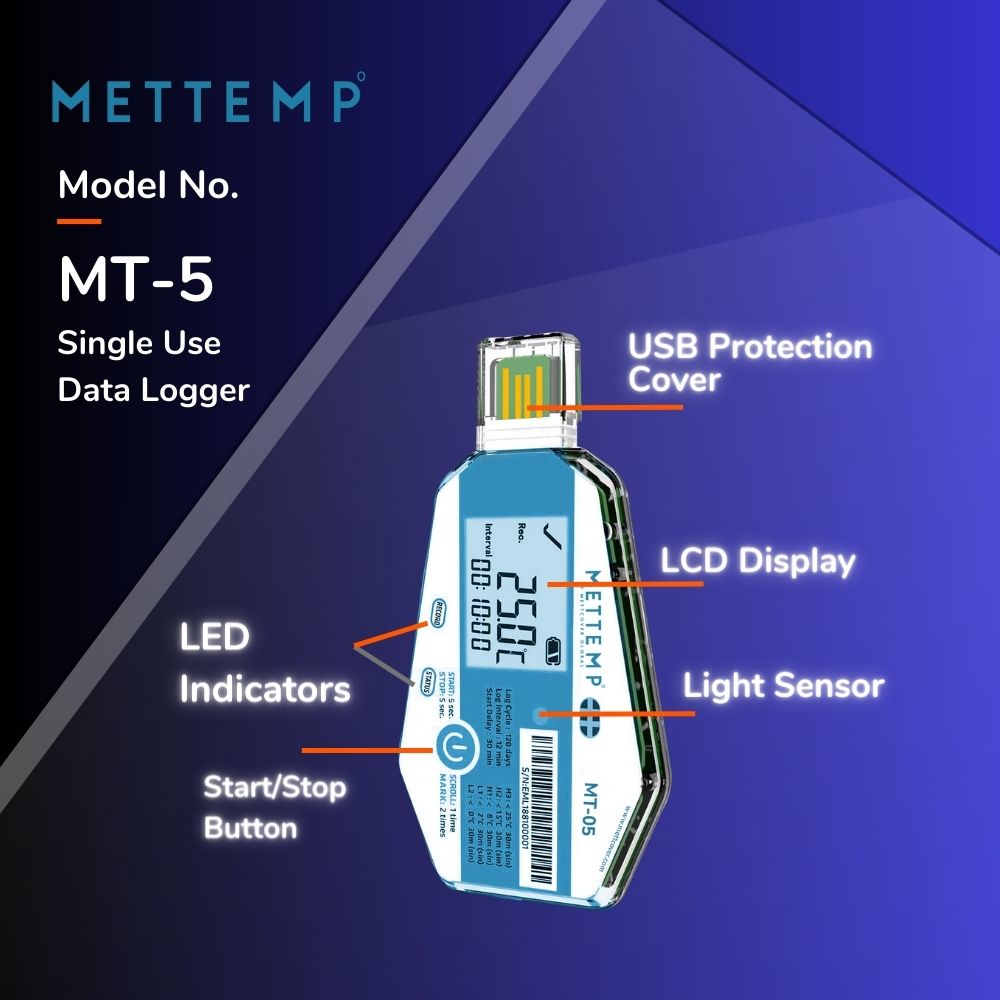

The transit of sensitive vaccines like those for Hepatitis demands maintaining a consistent temperature. It is easier said than done. The Mettemp MT 5 Data Logger was employed for this mission due to its superior features, including an enhanced accuracy of ±0.5℃, which is crucial when dealing with vaccines that demand precise temperature control.

Solution

Strategically placed within the Hepatitis vaccine shipment, the Mettemp MT 5 Data Logger continuously monitored the temperature. The MT 5 model includes a built-in backup shadow sensor, ensuring temperature recording even in case of (human) handling errors where the primary sensor may be accidentally stopped.

The data logger is also equipped with a light sensor, which proved instrumental in this scenario. It detected any violation of door opening operations during transportation, ensuring that the vaccines were not exposed to abrupt temperature changes due to mishandling.

The device’s precision-class internal temperature sensor ensured accurate readings throughout the journey. The real-time temperature data was displayed on the MT 5’s LCD screen, providing an intuitive indication of the conditions. The MT 5 single use temperature data logger offered an added layer of security. It automatically encrypted the data and generated a PDF report with password protection, adhering to the necessary regulatory and compliance standards such as CE (EN12830), RoHS, and FDA (21CFR). For comprehensive reporting, like all Mettemp data loggers, MT 5 is supported by Mettemp Log Tech software. The built-in USB connectivity allows users to access the reporting interface for Data Cycle Reports, Time & Heat Graphs and CSV files for easy sharing and data retrieval.

Conclusion:

Despite the handling error, the backup sensor (shadow sensor) continued to record temperature at preset intervals. On completing the transit route, the logger delivered a comprehensive report displaying optimum temperature fluctuations; which otherwise wouldn’t have been recorded if the back up sensor functionality was not available.

Data Loggers Save Money

While the primary goal of temperature data loggers is to ensure drug efficacy and safety, their role has broader implications. Consider the economics of it. By preventing spoilage or compromised efficacy of pharmaceuticals, temperature data loggers contribute significantly to cost savings. In the absence of vigilant temperature monitoring data, drugs could be rendered ineffective, leading to financial losses for pharmaceutical companies and healthcare institutions. Additionally, if a compromised drug were administered, it could result in health complications for the patient, further amplifying the economic burden on the healthcare system. The investment in temperature data loggers is a prudent economic decision that safeguards both the financial and physical well-being of the stakeholders.

The Economics of Quality with Mettemp Data Loggers

A precision data logger supported by diversified functions such as flexible logging intervals, multiple alarm thresholds and comprehensive reporting can safeguard the integrity of pharmaceuticals and wield a significant impact on the economic landscape of the industry.

Prolonged Performance and Cost-Efficiency: The Mettemp Advantage

One of the hallmarks of Mettemp Data Loggers is their extended calibration and battery life. These loggers are calibrated for a substantial two-year performance window. This means that once deployed, they provide accurate and reliable temperature monitoring for an extended duration, ensuring pharmaceuticals are continuously protected without the need for frequent recalibrations.

The battery life of Mettemp Data Loggers is aligned with their calibration period—also an impressive two years. This feature not only reduces the frequency of maintenance but also translates to cost savings. The avoidance of frequent battery replacements and recalibrations equates to a substantial reduction in operational costs for pharmaceutical companies, making Mettemp Data Loggers an economically prudent choice.

Zero Investment in Stock Maintenance:

At Mettcover Global, we take a client-centric approach by proactively managing stocks of data loggers. This means that pharmaceutical clients do not need to invest their resources in stock maintenance or worry about inventory management. The assurance of readily available, Mettemp Data Loggers eliminates the burden of inventory upkeep, allowing pharmaceutical companies to direct their investments and efforts towards their core operations and research endeavors.

The Assurance of Prompt Availability:

In supply chain dynamics, time is of the essence. Mettemp ensures that its data loggers are always available through a strategically designed global network. This network ensures the shortest lead time for order fulfillment, so clients can procure the loggers precisely when they need them. The prompt availability of Mettemp Data Loggers is more than a convenience—it’s a strategic advantage that can potentially translate into critical time savings for pharmaceutical companies.

Mettemp Cost-Efficiency Model: Total Cost of Ownership (TCO)

Understanding the economics of quality necessitates considering the Total Cost of Ownership (TCO). Mettemp Data Loggers, with their prolonged calibration and battery life, zero investment requirement for stock maintenance, and prompt availability, contribute to a lower TCO for pharmaceutical companies. The upfront investment in Mettemp Data Loggers is a smart economic decision that yields long-term dividends by reducing operational costs, minimizing inventory management expenses, and optimizing time resources.

Move your shipments with Mettemp Data Loggers; “Forward Only“

The innovation behind our data loggers (Mettemp) is constantly agile and evolving to align with industry needs and technological advancements. The journey towards the future involves integrating even smarter features into data loggers, enhancing real-time analytics, incorporating AI for predictive insights, and exploring blockchain for enhanced security and transparency.