The Science Behind Insulaite Thermal Pallet Covers

- Manager Mettcover

In pharmaceutical and life-science logistics, temperature control is non-negotiable. From airport tarmacs exposed to direct sunlight to unexpected transit delays, maintaining thermal integrity is one of the biggest challenges in global supply chains.

Insulaite® Thermal Pallet Covers by Mettcover are engineered to address these challenges through proven insulation science, reflective technology, and rigorous validation—offering a smarter, more cost-effective way to protect temperature-sensitive pharma cargo.

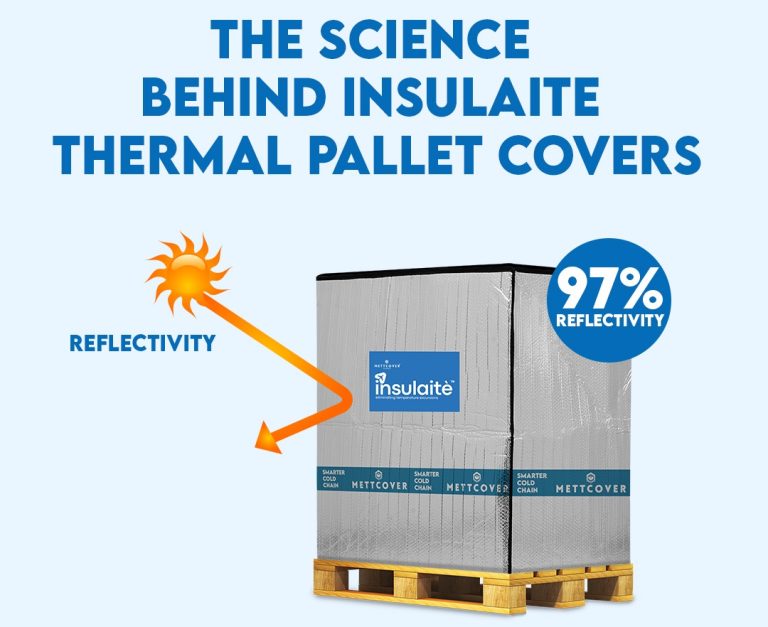

Reflectivity: The First Line of Thermal Defense

One of the key scientific principles behind Insulaite is thermal reflectivity.

Insulaite thermal pallet covers are designed with a highly reflective aluminium outer layer that reflects up to 97% of radiant heat. Instead of allowing solar radiation to penetrate the packaging, the reflective surface deflects heat away from the shipment—significantly reducing temperature rise during direct sun exposure on airport aprons and loading zones.

This reflective barrier is especially critical during:

- Prolonged tarmac exposure

- Peak summer operations

- Delays between aircraft loading and take-off

By addressing radiant heat at the source, Insulaite minimizes thermal stress before it reaches the cargo.

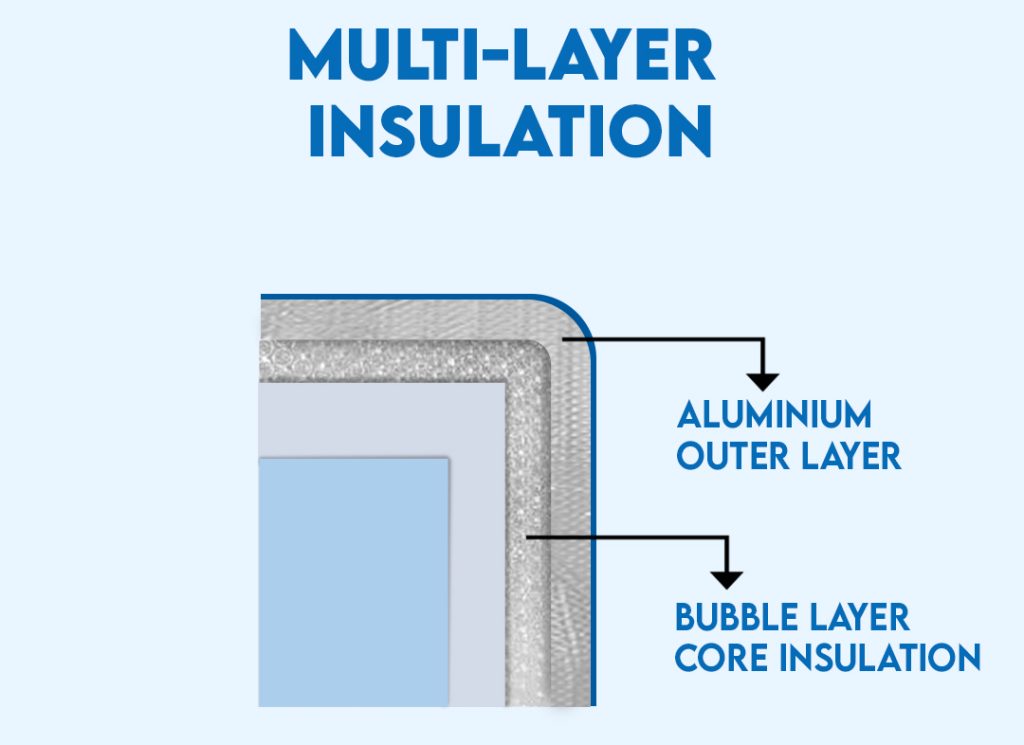

Multi-Layer Insulation: Engineered for Stability

How the layers work together

- Aluminium outer layer

Acts as a radiant heat reflector and weather-resistant shield. - Bubble core insulation layer

Traps air pockets that reduce conductive and convective heat flow. - Layered structure

Creates a thermal buffer that stabilizes internal temperatures.

This combination significantly reduces heat exchange between external conditions and the palletized cargo—keeping pharmaceuticals protected throughout transit.

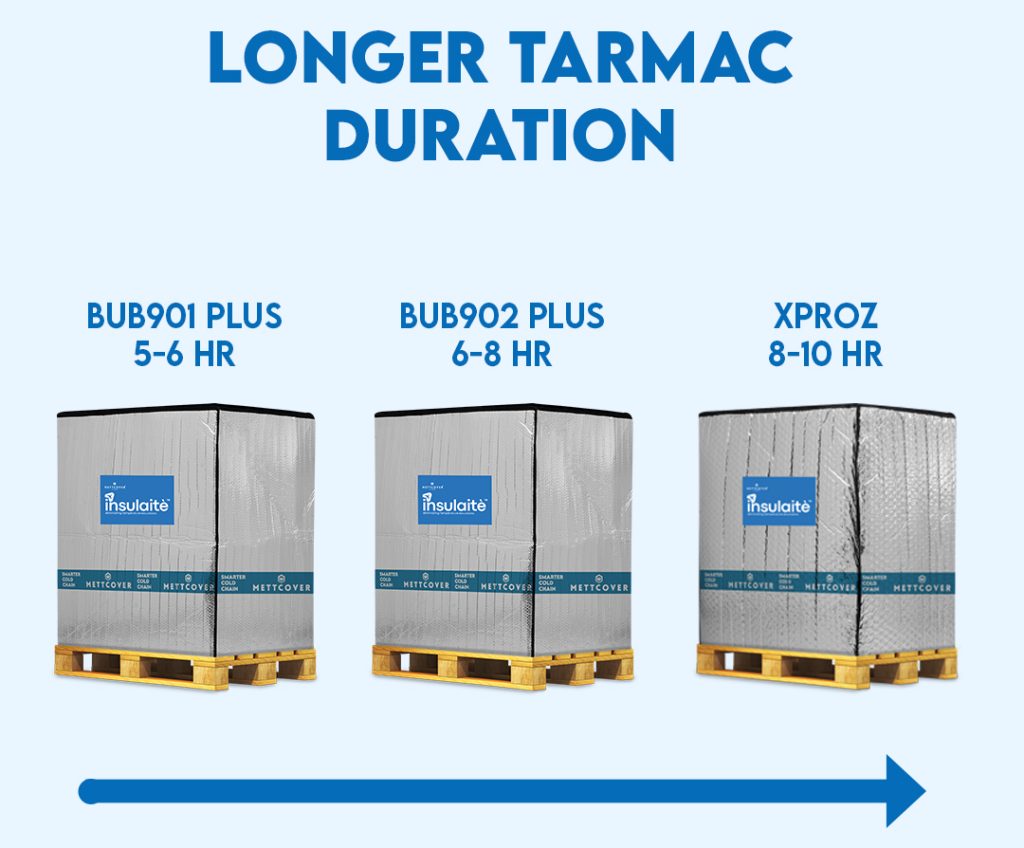

Longer Tarmac Duration Without Temperature Excursions

Different logistics scenarios demand different levels of protection. Insulaite offers multiple configurations designed for extended tarmac durations:

- BUB901 Plus: 5–6 hours

- BUB902 Plus: 6–8 hours

- XPROZ: 8–10 hours

As insulation performance increases, so does exposure tolerance—allowing shipments to remain stable even during longer ground handling times. This flexibility helps logistics teams select the right protection level based on route risk, seasonality, and operational complexity.

Validation & Testing: Proven Under Real Conditions

Thermal performance is only meaningful when it’s proven.

Insulaite pallet covers undergo comprehensive validation and testing, including:

- Climate chamber testing

- Direct sunlight exposure

- Hot summer and cold winter simulations

These tests replicate real-world transport conditions, ensuring consistent performance across seasonal extremes and global shipping lanes. The result is reliable, repeatable temperature protection that meets stringent pharmaceutical logistics standards.

Cost-Saving Protection for Pharma Logistics

Insulaite is not only about performance—it’s about efficiency and cost control.

By reducing temperature excursions, Insulaite helps:

- Lower product loss and deviation risks

- Minimize dependency on heavy active solutions

- Reduce packaging and operational costs

Reusable, lightweight, and easy to deploy, Insulaite offers a better way to protect pharma cargo without adding complexity to logistics workflows.

A Smarter Way to Protect Temperature-Sensitive Cargo

In today’s pharmaceutical supply chains, success depends on smarter packaging—not heavier packaging.

Through reflective technology, multi-layer insulation, validated performance, and flexible configurations, Insulaite Thermal Pallet Covers deliver dependable thermal protection exactly where it matters most.

From tarmac to destination, Insulaite keeps pharma cargo safe, stable, and compliant.