Analysis of BUB 901 Thermal Pallet Cover for maintaining payload at CRT. (Performance Summaries Included).

- Mettcover Global

A Medicine Wasted Is A Medicine Denied.

Anonymous

Temperature Controlled Logistic is a difficult job. Minor errors can lead to major losses. The cases of shipments getting rejected due to excessive temperature excursions is a significant monetary loss, however, the damage to the concerned shipper’s reputation and to society at-large is replaceable. For that precise reason, the transportation of pharmaceutical shipments is riddled with regulatory compliance.

In the context of cold chain, Controlled Room Temperature (CRT), refers to a specific temperature range mandated by regulatory bodies like IATA (International Air Transport Association) and U.S. Pharmacopeia (USP), for the storage and transportation of temperature-sensitive pharmaceutical products like pills and medicinal syrups. The CRT profile is crucial for maintaining the quality, efficacy, and safety of pharmaceuticals throughout their supply chain journey.

According to IATA, CRT range typically spans from 15°C to 25°C (59°F to 77°F) and U.S. Pharmacopeia (USP) also calls it “controlled ambient temperature,” emphasizing its importance in keeping medicines safe and effective.

Understanding Cold Chain Industry Challenges

The cold chain logistics industry is a crucial link in preserving the efficacy and integrity of temperature-sensitive products, including pharmaceuticals, biologics, vaccines, and perishables. Nevertheless, this domain grapples with several pressing challenges:

Temperature Variability: External temperature fluctuations during transit expose products to temperature excursions, posing a significant risk to their potency and efficacy.

Regulatory Compliance: Adhering to stringent regulatory standards, such as Controlled Room Temperature (CRT) guidelines, is paramount to ensure product stability and safety.

Thermal Insulation: Developing effective thermal packaging solutions that provide reliable insulation against external temperature variations is a continuous pursuit.

Transportation Efficiency: Enhancing transportation efficiency while maintaining the prescribed ambient temperature profile of temperature-sensitive cargo remains a central concern.

To mitigate such challenges, Mettcover Global’s R&D team has developed a wide range of insulation grade materials and BUB 901 being one them, offers validated insulation and effectively maintains CRT. At the heart of BUB 901’s Thermal Pallet Cover’s performance, lies its unique composition, comprising two highly reflective layers intertwined with a single layer of air bubble sheet. This ingeniously crafted insulation material is validated design for outstanding thermal insulation capabilities, safeguarding temperature-sensitive cargo with unmatched efficiency. Remarkably, despite its impressive performance, the BUB 901 Grade Thermal Pallet Cover boasts a mere 4.06 MM thickness, making it incredibly lightweight and agile.

BUB 901 Thermal Pallet Cover

The BUB 901 Grade cover is truly a game-changer in the world of cold chain logistics. Its key features sets it apart from conventional insulation solutions:

Double-sided Highly Reflective Surface and Bubble Insulation

Easy Installation and Tear-Resistant Design

Custom Sizes for Tailored Solutions

Grade Efficacy Validated in Worst-Case Scenarios:

Test Scenario

The pharmaceutical cargo (in this case) is expected to be exposed to extreme hot and cold external temperatures. during the transit journey. The primary objective of the case study is to assess the thermal insulation capabilities of Mettcover BUB 901 in preserving the Pharmaceutical Pallet Load at Controlled Room Temperature (CRT) while navigating the rigors of weather conditions.

Test Procedure:

To evaluate the thermal performance of Mettcover BUB 901 Thermal Pallet Cover, the pharmaceutical shipments underwent tests both in simulation chamber and in the direct sunlight. The strategically placed Temperature Recorders (Data Loggers) facilitated exact measurement of external temperature conditions (represented by the red line graph) and the temperature inside the pallet (represented by the blue line graph)

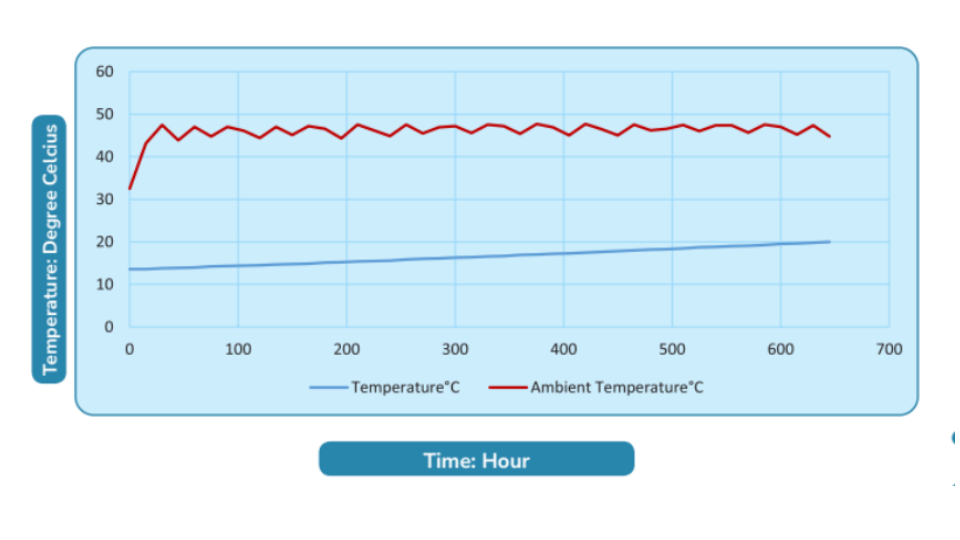

Environmental Chamber Test (Hot Weather Conditions):

In this test, the pallets containing temperature-sensitive pharmaceuticals were positioned in an environmental chamber simulating external temperatures equivalent to the Mean Kinetic temperature of (MKT) of 46°C. The test was conducted for 390 minutes (6.5 Hours).

TEST RESULTS

Mettcover BUB 901 effectively harnessed the principles of radiant heat transfer. The highly reflective layers of the cover minimized heat absorption from the external environment, while the air bubble sheet, acting as a convective air space, significantly reduced heat conduction. As a result, the pharmaceuticals remained cocooned within the prescribed temperature range, showcasing an exceptional average temperature drop rate (ATDR) of 97.5 minutes per 1°C and a total temperature drop rate (TTDR) of 6.5 hours.

Direct Sunlight Test

The Direct Sunlight Test aimed to assess Mettcover BUB 901’s thermal conservation performance under the unrelenting glare of solar heat & radiation which can dramatically elevate external temperatures and harm the potency of temperature-sensitive pharmaceuticals. The 5.25 hour test replicated the similar condition as any pallet may face on tarmac at Mean Kinetic Temperature of 44.4°C.

TEST RESULTS

Mettcover BUB 901 exhibited remarkable thermal insulation capabilities during the Direct Sunlight Test, mitigating the adverse effects of radiant heat. The reflective layers deflected a significant portion of solar radiation, preventing the cargo from overheating and the air bubble sheet efficiently trapped air, minimizing the heat conduction. The data revealed that the payload experienced a minimum temperature drop of 21.1°C and a maximum temperature limit of 25°C, with an Average Temperature Drop Rate ATDR of 93.75 minutes per 1°C and a Total temperature Drop Rate (TTDR) of 5.25 hours.

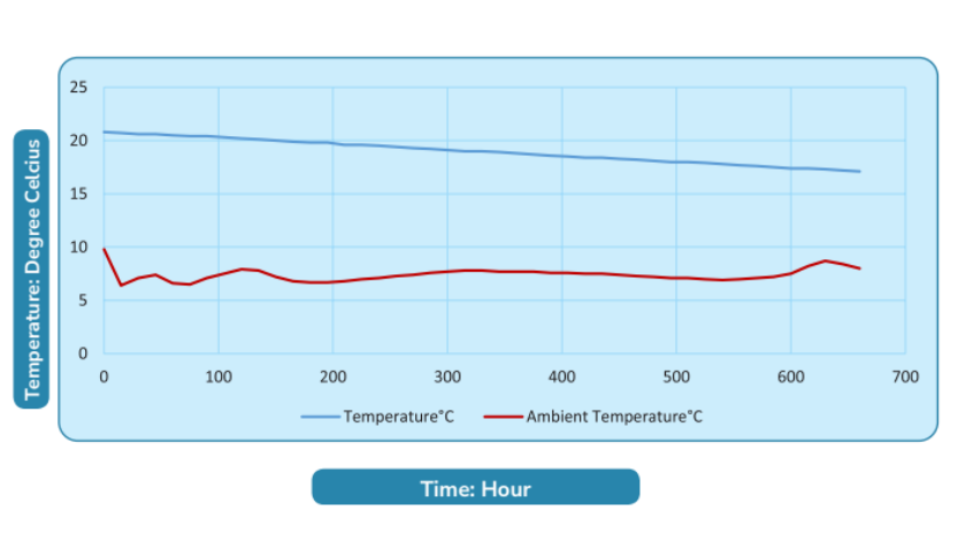

Environmental Chamber Test (Cold Weather Conditions)

BUB 901 covered Pallet was tested, simulating the Mean Kinetic Temperature of 7.4°C (external temperature). The test routine lasted for 10.75 hours with external temperature range varying between 6°C to 10°C, that of cold winters.

TEST RESULTS

Mettcover BUB 901 demonstrated robust resilience in combatting the cold excursions during the test, nullifying adverse affect of cold temperature on the cargo. The data reflects that the temperature inside the pallet recorded a maximum rise up to 21.1 °C during over 10 hours of testing the cover in cold conditions. The performance in cold conditions further reflects that PCMs or gel packs are not required in this case, when using BUB901 cover.

Conclusion

The case study of Mettcover BUB 901 underscores its outstanding thermal engineering performance as an effective insulated packaging product for temperature-sensitive cargo. Leveraging principles of heat transfer and thermal insulation, the thermal pallet cover successfully maintains the desired controlled room temperature (CRT) profile during transportation under the most challenging external conditions.

The success of the lab-test conducted by us was replicated in the internal tests done by the pharmaceuticals company; further validating the excellent insulation capabilities of Material Grade BUB 901 for maintaining Controlled Room Temperature (CRT) in hot & cold weather conditions. It was deduced that the exceptional performance of BUB901 Grade in the cold weather conditions also nullifies the use of PCMs while maintaining pallet load integrity in this particular scenario.

________________

Advertisement

_______________

The comprehensive data collected during the trials showcased the BUB 901 Grade Thermal Pallet Cover’s extraordinary insulation properties and its ability to mitigate temperature drop rates under extreme ambient conditions. These results unequivocally establish BUB 901 as the quintessential thermal pallet cover, ensuring the security and integrity of temperature-sensitive cargo during transportation.

Choose Mettcover Global and start a transformative journey towards a safer, more resilient cold chain, safeguarding your cargo and elevating your business to unprecedented heights.

Want your own validation tests done? Click HERE

To learn more about Mettcover Thermal Pallet Covers and the 16 grades of insulation material Click HERE