5 common mistakes while using Cold Chain Data Logger. Thank Us Later.

- Mettcover Global

Data in itself is static but when you collect and use it right, it can change your world.

The adage, “Good things come in small packages” is truest in the case of cold chain data loggers. They not only form the very back bone of supply chain, temperature data loggers are the steadfast guardians of your shipment’s temperature integrity. For once, all of us will agree that in the world of cold chain logistics, surprises are never welcomed. Temperature monitoring and recording of shipments in transit and storage remove that element of surprise, adding the much needed resilience to any supply chain route involving movement of temperature sensitive shipments. In that context, PDF Data Loggers are the coolest gadgets, providing accurate and reliable temperature data of your precious cargo; tracking their wellbeing, when you can’t.

But even these superheroes of gadgets have their kryptonite. As sellers of Mettemp Data Loggers that are specifically built for cold chain success, almost every day, we resolve queries for our clients about how to correctly use data loggers. Here are the top 5 mistakes people make while using temperature data loggers. These are common errors that the best of us are guilty of.

Is the Calibration Certificate of your data logger MIA (Missing in Action)?

Think about it like this. Your data loggers are like mini thermometers that have been pre-tuned to perform specific functions and record specific temperatures. Ignoring or not checking a calibration certificate is like buying a car without knowing its specs.

Calibration is the heart of temperature accuracy in PDF Data Loggers. A study conducted by Frosst et al. (2020) demonstrated that regular calibration significantly improved data logger accuracy, reducing temperature discrepancies by up to 90% in various cold chain scenarios. For instance, in the pharmaceutical industry, precise temperature control is critical to ensure the potency and efficacy of vaccines and medications. Neglecting calibration can lead to temperature variations that compromise product quality and regulatory compliance.

Data loggers can be easily lost in placement. Where did you place yours?

Location, location, location! Data loggers are like real estate agents, and they need the perfect spot to do their magic. Placing them in the wrong nooks can lead to false readings. Remember, it’s all about finding the sweet spot – consider product packaging, shipment size, and spread out loggers for a smooth ride.

Proper data logger placement can make or break cold chain operations. A case study by Cold Logistics Solutions (CLS) examined the impact of data logger positioning in a seafood export shipment. Placing the data logger near the shipment’s exterior resulted in temperature fluctuations due to external temperature exposure, whereas placing it centrally within the shipment provided consistent and accurate temperature readings.

Our client, an ice cream manufacturer who is regularly shipping the delectable treats across France, followed our advice and placed the data loggers at strategic locations inside the freezer trucks. Correct placements helped monitor temperature variations accurately, ensuring the ice cream arrived in perfect condition at retail stores, delighting customers and minimizing wastage.

Did you set the correct alarm threshold in your data logger?

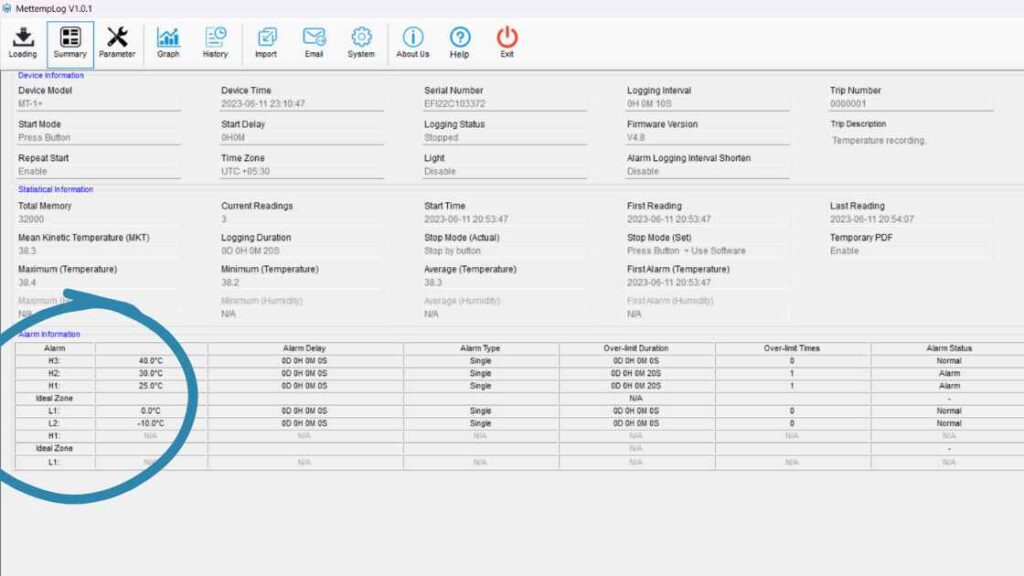

Data loggers have alarms too; some visual, meaning that they will show on your reports marked in red and some with an audible buzzer. Most single use data loggers, like the Mettemp MT 5 model allow setting alarm thresholds up to 5 points, namely H1 H2 H3 for setting the higher side of temperature threshold and L1 L2 for mapping the lower range. Setting the correct alarm threshold enables you to make data driven decisions and in determining the true integrity of your shipments.

Make sure that you set the optimal temperature recording range which best suits the product you are moving or storing. A PDF data logger in its ready-report will show all excursions beyond these values, marked in RED. Therefore giving you a complete visibility on temperature breaches and their duration.

Image: Screenshot of Mettemp Log Free Data Logger Software.

Similar Articles:

What is a Temperature Data Logger? How it works?

White Paper on the Efficacy of Data Loggers in the Pharmaceuticals Cold Chain Management.

Are you backing up your data? And backing the back-up too?

Data loss is a data logger’s worst nightmare – it’s like losing your phone. Avoid this by having a backup plan. Store your data in more than one place, like a tech-savvy squirrel hoarding nuts.

Data loss in the cold chain can be catastrophic, impacting product quality and regulatory compliance. A study by the International Journal of Refrigeration (IJR) highlighted that data backup measures, such as cloud storage or localized servers significantly improved data logger reliability and data accessibility during audits.

Consider a case where a medical research institute experienced a power outage that affected their cold storage unit, resulting in data logger data loss. Having a robust data backup plan could have allowed them to retrieve crucial temperature data, providing essential evidence for research validation.

Are you using expired or outdated Data Loggers?

Data Loggers come with an expiration date which will be clearly mentioned on the device and on the calibration certificate. Don’t ignore it. Using outdated loggers is like relying on a dead flashlight in the dark.

In a real-world example, when a pharmaceutical distributor knowingly or unknowingly used expired data loggers for a shipment of medications. Upon inspection, health authorities flagged the shipment for potential temperature excursions, leading to a costly product recall and damage to the company’s reputation. Maintaining an up-to-date inventory of data loggers and adhering to their validity periods is crucial for reliable temperature monitoring.

In Mettemp Data Loggers, you can easily check the expiration date written on the device and on the calibration certificate provided with every data logger. Make sure that you check the details after matching the serial number on the device and the certificate.

Keep a check on battery levels.

Low batteries? Keep a prudent vigil on your data logger’s battery levels, like a responsible parent watching their kid’s energy level.

Set up low-battery alerts and swap those batteries like a pro to keep the data flowing. Low battery levels can interrupt data logger operation, resulting in data gaps and compromised temperature monitoring. A study by the Journal of Cold Chain Management (JCCM) emphasized the significance of battery monitoring and proactive battery replacements to avoid data logger downtime.

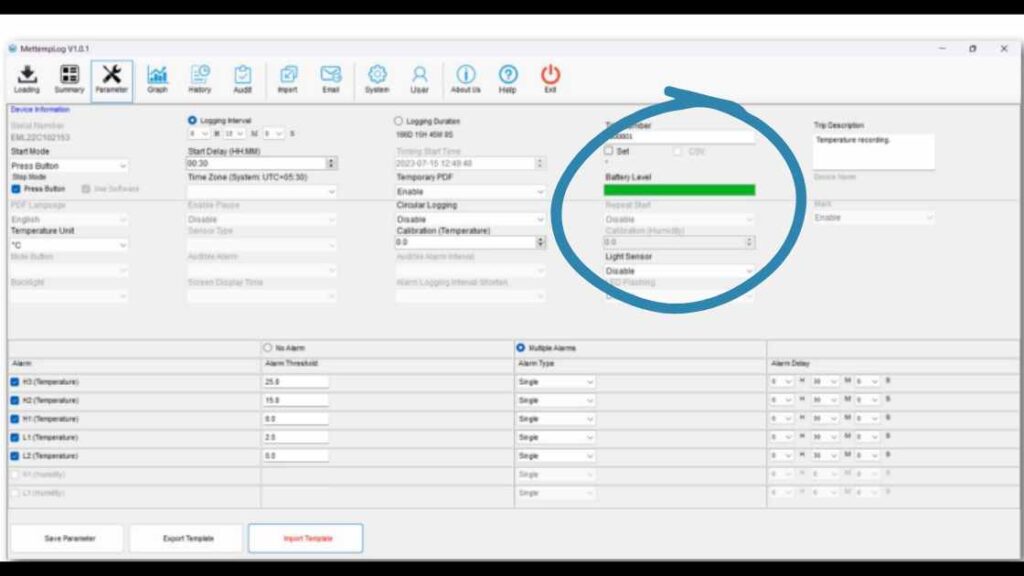

If you are using Mettemp Data Loggers then all you need is to connect your device with any laptop and open Mettemp Log Software. In parameter header, the battery life is boldly highlighted in Green (if charged) and in red (if depleted).

Inset – Battery Indicator in Mettemp Log interface indicating “Full Battery” of data logger.

Temperature Data Loggers are your trusted ally in the cold chain, ensuring your temperature-sensitive goodies reach their destination safe and sound. By avoiding these common mistakes, you’ll unleash the full potential of your data loggers, bettering your efficiency and quality. So, go forth, wise ones, and let your Data Loggers be your guiding light by using them right!

Have a question about how to use Temperature Data Loggers? Connect with Mettcover Expert.